Among those famous China pcd grinding wheels manufacturers,Website:://.herohomecn.com, Yinglong Superhard Materials Manufactory is a professional such supplier, welcome to buy sdc grinding wheel, grinding wheel for pcd, diamond vitrified grinding wheel, pcd insert grinding wheel production with our factory.

Vitrified Grinding Wheel for PCD InsertsGeneral Information; PCD represene diamond, it is a superhard synthetic abrasive. Mostly used for processing of cutting nts polycrystallitools. It is composed of micron-sized with very hard diamond grains. These grains are bound by metal bonds and placed on a sintered carbide base. That makes it possible to create a product with excellent properties, which is broadly used in machining.Vitrified bond diamond wheel for Precision Grinding of PCD; Vitrified bond Diamond grinding wheels have characteristics of sharp cutting, high efficiency, long life, less heat and blocking generated, easy control the precision and easy dressing. Application of Vitrified bond grinding wheels:Vitrified bond diamond grinding wheels: Mainly used for machining ceramic, cermets, optical glass, PCD, PCBN, CVD, natural diamond, stones and so on. Compared with resin bond wheel and metallic bond wheel, ceramic bond diamond wheel could process at least2 to 3 times produces under same at the same time, it do save customers' time and promote produce efficiency. Regular Grinding Wheels for PCD Inserts;

Item

Diameter

(MM)

Thickness

(MM)

Inner Diameter

(MM)

Width

(MM)

Thickness

(MM)

Shape

Grain Size

Vitrified Bond

Diamond Grinding Wheesl

100

40

20/32/40

5/10/15

3-10

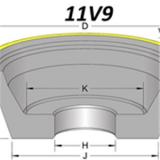

6A2

12A2

D6

D9

D15

D20

D35

125

40

20/32/40

5/10/15

3-10

150

40

20/32/40

5/10/15

3-10

150

10

20/31.75/32

5/10

3-10

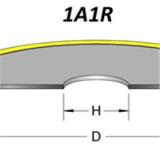

1A1

175

10

20/31.75/32

5/10

3-10

350

90

260

13

10

6A2

250

50

215

8

6

6A2

350

50

310

10

10

6A2

Shorter set up times as a result of longer dressing intervalsIncrease process stability.Improves cutting-edge chipping with better cutting ability.Higher cutting ability with high profile retention.How to purchase Grinding Wheel from us?

By certification

By certification